My verrry eco-minded friend, Waylon Lewis, lives on “the Hill” [a neighborhood in Boulder, Colorado next to the University of Colorado]. He runs elephantjournal.com, an online blog that focuses on yoga, organics, active citizenship and sustainability, among other things.

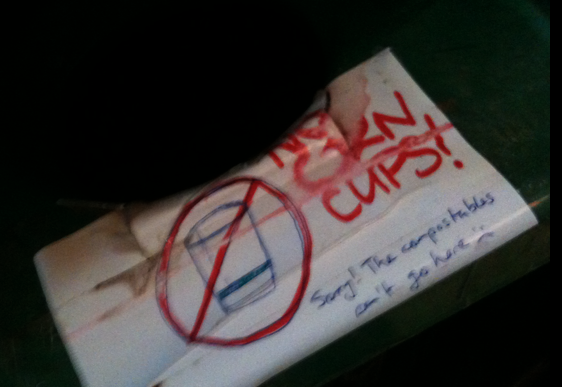

One of the perennial biggest issues plaguing Waylon’s neighborhood are the red Solo cups littered all over the ground. The red cups are made from petroleum based plastic (PET). A direct descendant of a party culture full of kegs and beer pong, they’re notorious on campuses around the nation (beer pong is a game played with beer, a table, and most importantly, 20 of those infamous red cups. It can be seen played at most parties these days, and is only growing in popularity).

One day after hearing Waylon complain about the cups for the 80th time, I suggested we start marketing those biodegradable cups made out of polylactic acid (PLA), more commonly known as corn plastic. They’re already made, of course—by Boulder’s own Eco Products—and popular with eco-minded party people everywhere. Waylon added the idea of making the cups a solid green. We figured the cups would sell themselves, greening college campuses, concerts, sports events…

As we looked into the cups a little more, we found some major problems. The corn used in these cups comes from big-business-owned, genetically modified, federally-subsidized monculture corn. Additionally, the PLA is extremely energy intensive to produce—probably one of the more ridiculous uses for what would otherwise be food. And finally, the cups aren’t really compostable—they need to be taken to a recycling center, not your compost heap, where they can be “composted” at high temperatures. PLA may be better than petroleum based plastic; but other things, such as recycling or using good old fashioned glass or porcelain partyware are better earth-friendly options.

Corn as a renewable resource is, of course, not bad in itself. The problem begins with the major companies that grow most of the corn in the United States. The main producers of corn in the U.S. are Monsanto, Archer Daniels Midland, and Cargill Incorporated.

If Cargill, based out of Minnesota, were a publicly-traded company, it would be one of the ten biggest Fortune 500 companies. As a privately-owned and operated company, its empire encircles agriculture. Cargill imports and exports grain, salt, cotton, and meat from 65 countries all over the world. Being one of the world’s biggest companies, its main goal is profit. To produce these big profits, Cargill has turned to science and GMOs. By modifying the corn, they claim to have increased the amount grown on acre by almost 40 percent in 40 years. Due to modifications, the corn is now more resistant to disease, pests, and herbicides than ever before. The stalks are thicker, to withstand wind storms and to make it easier to harvest.

Cargill also owns NatureWorks. NatureWorks, with accounts like Walmart, produces most of the PLA in the United States.

GMOs are not natural, and remain largely a mystery to many Americans. What we do know is not as scary as what we don’t know. An example from Saynotogmos.org about the nature of GMOs: “Genes from an arctic flounder, which has “antifreeze” properties may be spliced into a tomato to prevent frost damage.” One of the main bonafides fore PLA is the notion that it’s (technically) compostable. That’s all good and dandy if the corn is organic and non-GMO. But no one knows when the seeds of GMOs become intermingled into other foods. I for one would not want antifreeze on my compost, or in any of my food for that matter.

An article by Elizabeth Royte in the Smithsonian.com states that, “according to a biodegradability standard that Mojo helped develop, PLA is said to decompose into carbon dioxide and water in a “controlled composting environment” in fewer than 90 days. What’s a controlled composting environment? Not your backyard bin, pit or tumbling barrel. It’s a large facility where compost—essentially, plant scraps being digested by microbes into fertilizer—reaches 140 degrees for 10 consecutive days.

If PLA is put into a landfill it can last as long as PET; 100 to 1,000 years. It can be recycled, but not in the same recycling plant as PET products—if enough PLA gets mixed in with petroleum plastic, it can gum up the works. Traditional recycling plants must pay to get the two sorted and pay to ship the PLA elsewhere.

It’s crazy energy intensive to make “plastic” from a kernel of corn. It takes as much petroleum to make a petroleum-based plastic as it does to make a PLA cup—defeating the eco-responsible purpose. PLA is made in a wet mill, and it takes gallons and gallons of water to soak and process the corn into plastic (all my research on the web seemed to back that up). Ethanol, a similar process, is also laughably energy-inefficient.

We still need to look at the bigger issue of how many containers are being used per day. Everybody knows the feeling of buying a new electronic device…and needing the jaws of life to get it out of all the packaging! We still need to be recycling the old plastics we have in existence. For things that need to be durable, like televisions, recycled petroleum plastic is a better answer. PET is a better alternative for things that are not already successfully recycled like packaging. And paper packaging is still a better alternative when possible.

There are companies, such as Eco-Products, that produce some organic non-GMO cups. The demand is out there, and companies are listening. Cargill and its subsidiary, NatureWorks, are starting to make a small amount of “clean” PLA. Companies are out to make money, remember: so if we the customer demand it, the companies will eventually do it. After all, it was the demand for an alternative to PET that led to the market for PLA.

To quickly throw some more fuel on the fire—amidst questions of the morality of turning food into packaging when so many people in the world are hungry, the Smithsonian Magazine quoted Lester Brown, president of the Earth Policy Institute, “already we’re converting 12 percent of the U.S. grain harvest to ethanol,” he said. The USDA projects that figure will rise to 23 percent by 2014. “How much corn do we want to convert to nonfood products?” Brown asks. It is no secret that there are hungry people in almost every corner of the world. So, why do we need to use land that could be used to grow food to satisfy our beverage craving.

The world craves a renewable fuel source that will solve the current energy crises. People are looking for a silver bullet to calm their fear of peak oil and climate change. Corn ethanol and PLA are the current bullets. However good they may become, they are only a piece. Using all three parts of the recycling motto can make more of a difference. We should first reduce, reuse, recycle. Then make more stuff out of corn.

Waylon and I got ahead of ourselves with saving the world one beer pong game at time. The first thing we should be doing is picking up the red cups and recycling them. We could start a program to encourage others to do the same. Once that is a success we could start to realize our dream of a world full of green organic non-GMO PLA super cups!

Read 11 comments and reply